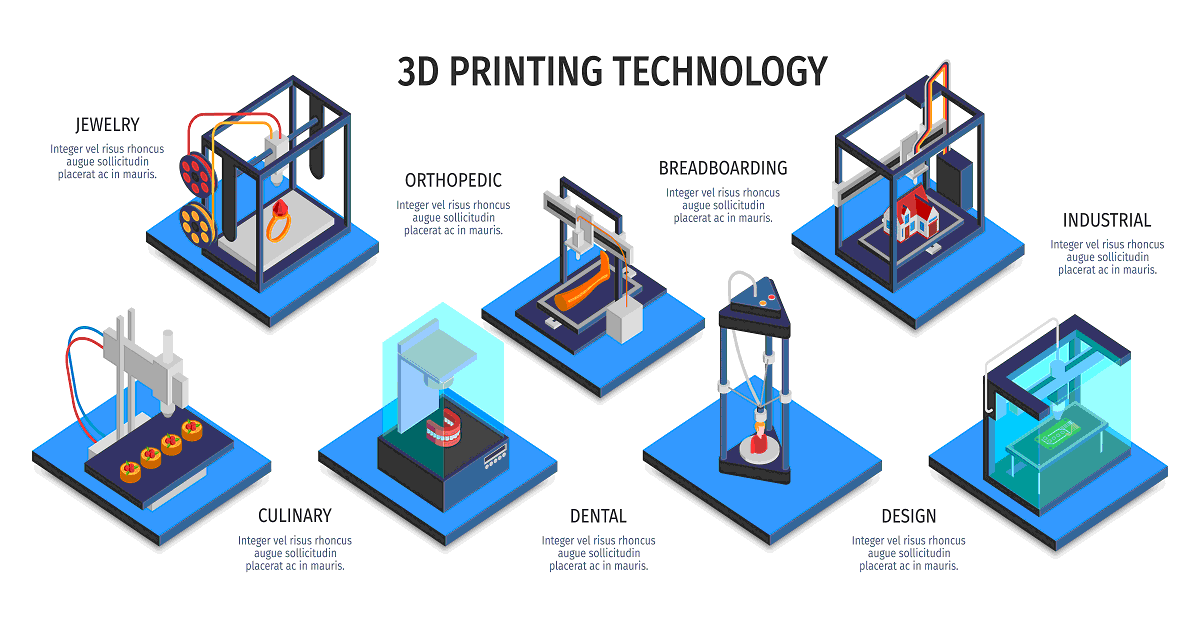

Introduction: 3D printing, also known as additive manufacturing, has been making waves in various industries for its ability to produce complex shapes and designs with speed and precision. This technology is now being embraced by the manufacturing industry, offering new opportunities for customization, cost savings and improved production efficiency. In this article, we will take an in-depth look at 3D printing in manufacturing, its advancements, impact on traditional methods, and future prospects.

Overview of 3D Printing and Its Benefits in Manufacturing:

3D printing is the process of creating a three-dimensional object by building up layers of material, such as plastic, metal, or composite materials. The object is created by following a digital blueprint, or model, and can be manufactured in a matter of hours or days, as opposed to traditional manufacturing methods that can take weeks or months.

Benefits of 3D Printing in Manufacturing:

- Speeds up the production process: 3D printing allows manufacturers to quickly produce prototypes, test their design and make necessary modifications, without the need for tooling or setup time.

- Improves customization: With 3D printing, manufacturers can produce unique, customized products with ease, reducing the need for large production runs and reducing waste.

- Cost savings: The use of 3D printing in manufacturing reduces the cost of producing prototypes and low-volume products, making it an economical alternative to traditional methods.

- Efficiency: 3D printing allows for more efficient use of materials and reduces the need for large inventories, leading to lower costs and improved production efficiency.

Advancements and Latest Technology in 3D Printing:

The 3D printing industry is rapidly evolving, and new advancements are being made in materials, speed, accuracy, and affordability. Some of the latest technologies include:

- Metal 3D printing: Metal 3D printing is being used to produce aerospace and medical components, offering a strong, lightweight alternative to traditional metal manufacturing methods.

- Multi-material printing: Multi-material printing enables the production of complex objects with multiple materials and properties, providing new opportunities for customization and innovation.

- High-speed printing: High-speed 3D printing technologies are being developed, reducing the time it takes to produce objects and increasing production efficiency.

Impact of 3D Printing on Traditional Manufacturing Methods

3D printing is changing the way products are manufactured, with the technology offering a more cost-effective and efficient alternative to traditional manufacturing methods. One of the key benefits of 3D printing is the ability to produce complex designs that would be difficult or impossible to manufacture using traditional methods. This results in reduced production time, as products can be manufactured faster and with less waste.

Another advantage of 3D printing is the ability to produce custom-designed products on-demand, without the need for expensive tooling or molds. This results in lower production costs and increased flexibility for manufacturers, as they can quickly adapt to changes in demand or design specifications.

Despite these benefits, the widespread adoption of 3D printing in the manufacturing industry has not been without its challenges. One of the main limitations of 3D printing is material limitations, as not all materials can be 3D printed. This limits the range of products that can be manufactured using 3D printing technology, and may require manufacturers to consider alternative materials.

Real-life Examples and Case Studies of Companies Using 3D Printing in Manufacturing

One of the most successful and well-known case studies of companies using 3D printing in manufacturing is GE Aviation. The company utilized 3D printing to produce fuel nozzles for aircraft engines, resulting in reduced production time and cost. By using 3D printing technology, the time to produce a fuel nozzle dropped from a few months to just a few days. This speed and efficiency also reduced the production cost of each nozzle by 30%.

Nike is another company that has embraced 3D printing in manufacturing. The company uses the technology to produce prototypes and limited edition shoe designs. Nike's partnership with 3D printing company Carbon has allowed them to create high-performance running shoes with 3D printed soles. This has not only allowed for quicker prototyping and testing, but also for the creation of customized shoes for specific athletes.

Another example of a company using 3D printing in manufacturing is Adidas. The company has used 3D printing to produce prototypes and even final products for their line of shoes. In 2016, they launched the world's first 3D-printed running shoes. The company also utilizes 3D printing to create customized shoe insoles, giving customers the ability to purchase a truly unique product.

According to a report by MarketsandMarkets, the global 3D printing market size is expected to reach $35.6 billion by 2027, growing at a CAGR of 15.2% from 2020 to 2027. These examples and statistics showcase the growing trend of companies utilizing 3D printing in manufacturing and the potential for future growth in the industry.

Overall, the use of 3D printing in manufacturing has the potential to revolutionize the industry. The technology offers benefits such as improved production efficiency, cost savings, and customization opportunities. Companies such as GE Aviation, Nike, and Adidas have already successfully utilized 3D printing in their manufacturing processes, and this trend is expected to continue to grow in the future.

Challenges and Limitations of 3D Printing in Manufacturing

Despite the numerous benefits and advancements in 3D printing technology, there are still some challenges and limitations that must be addressed in order for it to be fully integrated into the manufacturing industry.

One of the main challenges is the cost of 3D printing equipment and materials, which can be expensive and limit its accessibility to smaller manufacturing companies. Another challenge is the limitations in the size and complexity of parts that can be produced with 3D printing, as well as the limited availability of specialized materials.

Additionally, there is also a need for skilled professionals to operate and maintain the 3D printing equipment, which can be a barrier for some companies. Furthermore, there are concerns about the environmental impact of 3D printing, including the waste produced and the energy consumption required for the printing process.

Future Prospects of 3D Printing in the Manufacturing Industry

The future of 3D printing in the manufacturing industry is extremely promising, with the technology expected to play a major role in shaping the industry in the coming years. As the technology continues to advance, the range of materials that can be 3D printed is likely to increase, and the cost of equipment and materials is expected to decrease.

The ability to produce custom-designed products on-demand, combined with improved production efficiency and reduced production time, means that 3D printing has the potential to revolutionize the manufacturing industry. With the global 3D printing market expected to reach $35.6 billion by 2027, growing at a CAGR of 15.2% from 2020 to 2027, it is clear that the technology is here to stay.

Conclusion

In conclusion, 3D printing has the potential to revolutionize the manufacturing industry and provide new opportunities for customization, cost savings, and improved production efficiency. With advancements in technology and the increasing demand for customization, it is expected to have a significant impact on traditional manufacturing methods and drive growth in the industry.

As the market for 3D printing continues to grow, manufacturers, technologists, entrepreneurs, innovators, and business owners should consider the potential of this technology in their operations. By leveraging 3D printing, they can not only improve their production processes but also gain a competitive advantage in the industry.